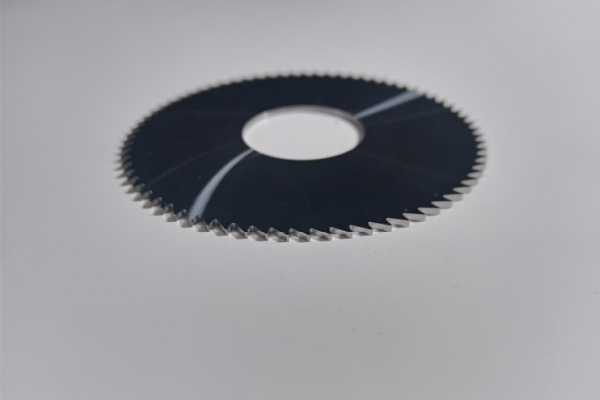

Solid Tungsten Carbide Saw Blade

Description

Solid carbide saw blade cuts plastic and PVC board,all ferrous steels and most non-ferrous metals, such as titanium, stainless steel, bronze, aluminum and copper.

It offers a highly precise result thanks to controlled sharpening and coatings that improve its durability and resistance.

Features

● 100% virgin tungsten carbide materials

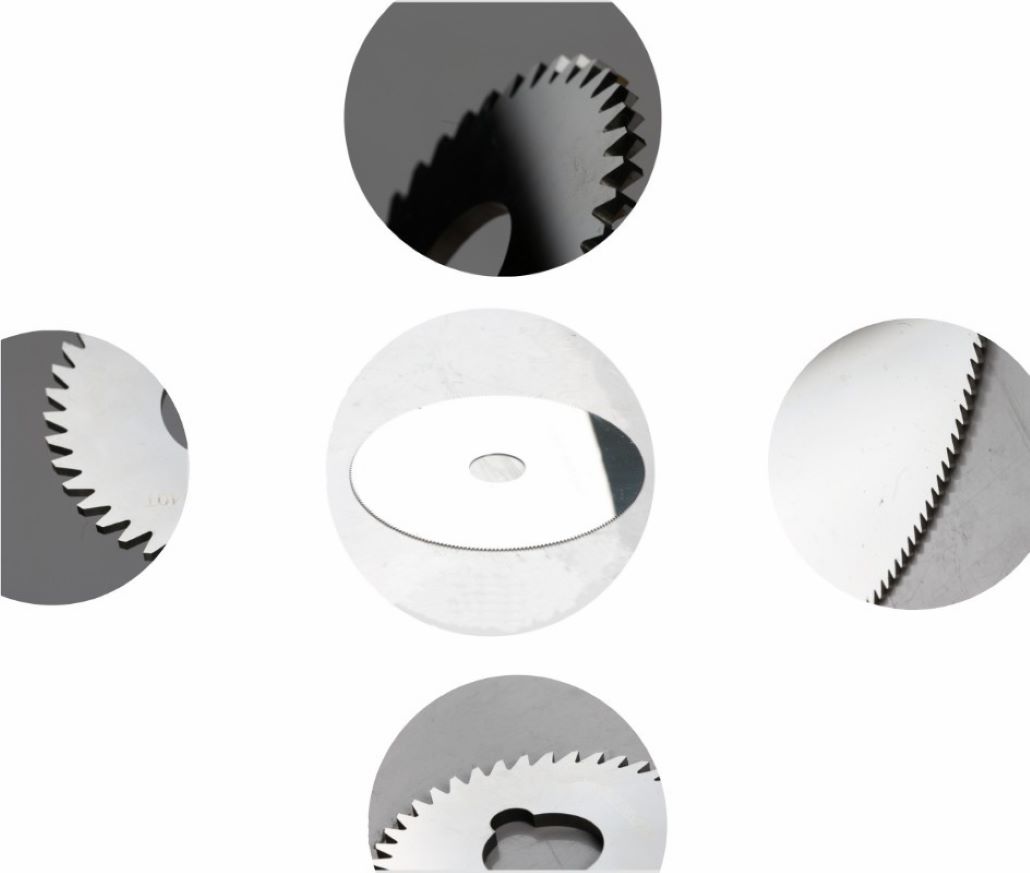

● Different teech type are available

● Varied sizes and grades for each application

● Excellent wear resistance & durability

● Great adaptability and No chipping

● Competitive prices

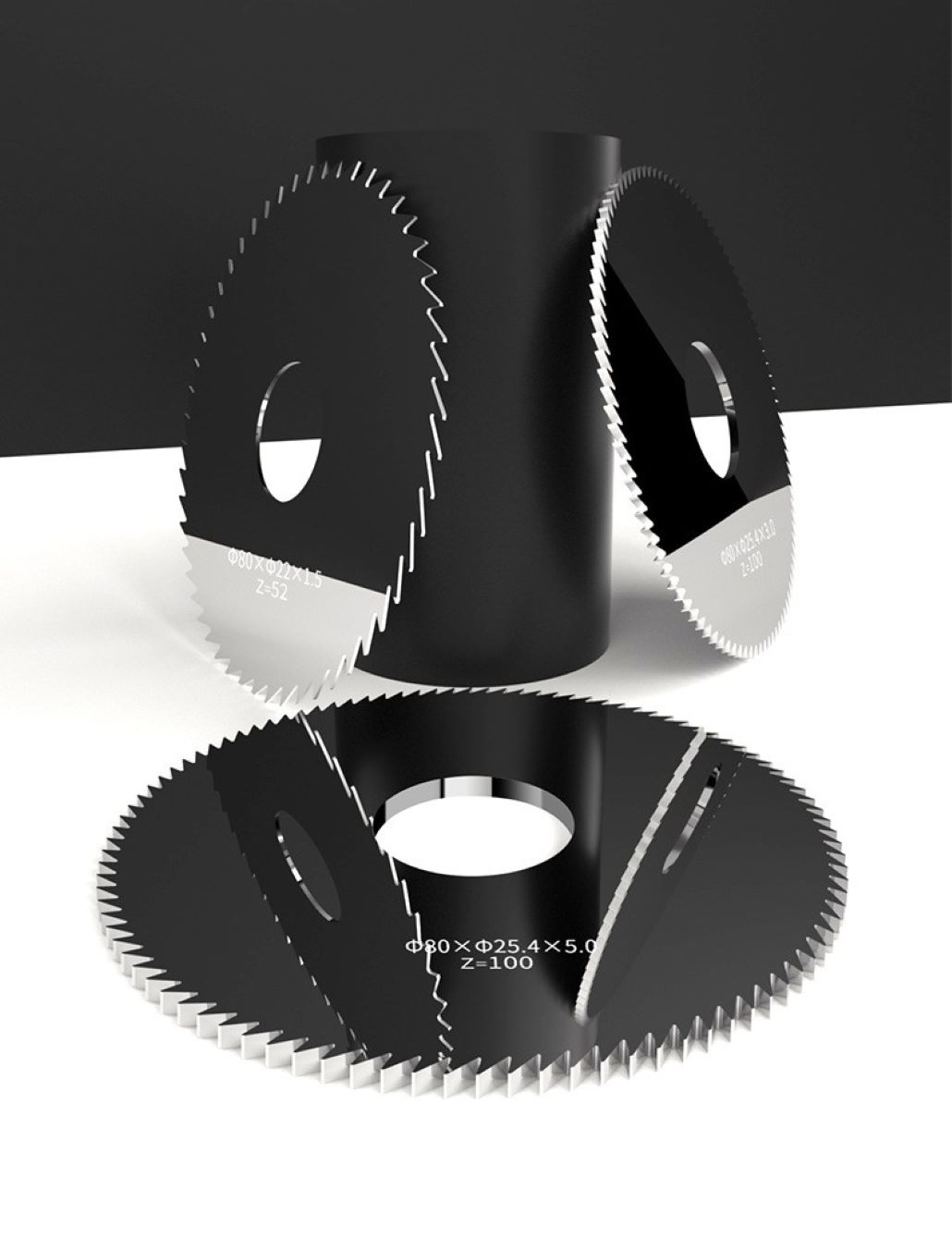

Photos

01 Smoother Cut

Sharp cutting and smooth chip removal.

Mirror effect to improve cutting performance.

02 High Wear Resistance

Saw blade is high hardness and wear-resistant.

More cost-effective.

03 Long Lifetime

Long life service, accuracy and resists bending and deflection.

04 Scientific Research

Cutting sharp,no burrs, no chipping.

05 OEM

Non-standard Customization Are Acceptable.

Advantage

1.Over 15 years manufacturing experience with advanced equipment and technology.

2. High precision, Fast cutting, Durability and Stable performance.

3.High polished mirror grinding. Low friction and excellent sliding value are guaranteeing an excellent cutting

performance and long tool life.

4. Allow higher cutting speeds and feed rates as well a high output. Their lifetime is significantly increased.

Professional custom non-standard special alloy according to customer’s drawing, dimension and requirement.

Application

Ideal for meeting the challenges of the metallurgical, aeronautical or automotive industries, it also has other areas of application. The carbide saw blade allows high cutting conditions.

Thanks to the definition of cutting parameters adapted to your needs, our team is able to design carbide cutters in perfect adequacy with each business challenge.

Thanks to our technical team, we are able to design the tool you need.

OUR QUALITY CONTROL

Quality Policy

Quality is the soul of products.

Strictly process control.

Zero tolerate of defects!

Passed ISO9001-2015 Certification

Production Equipment

Wet Grinding

Spray Drying

Press

TPA Press

Semi-Press

HIP Sintering

Processing Equipment

Drilling

Wire Cutting

Vertical Grinding

Universal Grinding

Plane Grinding

CNC Milling Machine

Inspection Instrument

Hardness Meter

Planimeter

Quadratic Element Measurement

Cobalt Magnetic Instrument

Metallographic Microscope