Tungsten Carbide End Mill

Description

Tungsten carbide end mill are extremely heat-resistant and used for high-speed applications on some of the hardest materials such as cast iron, non-ferrous metals, alloys and plastics. They have an excellent performance rate and abrasion resistance and can be used on a wide variety of materials.

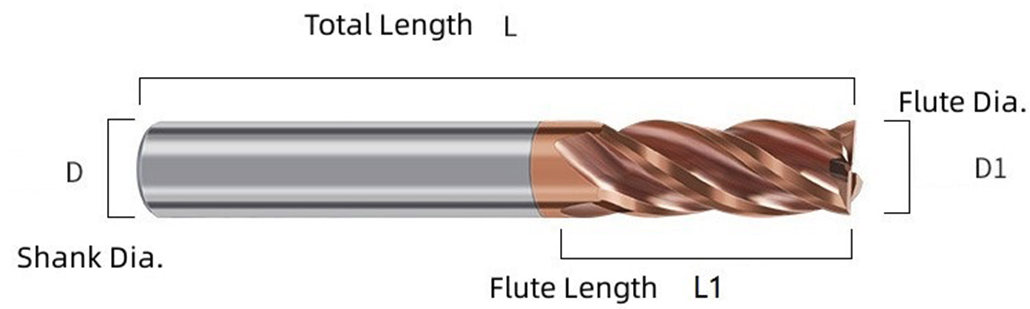

Specification of Tungsten Carbide End Mill

| Specification | Flute Dia. D1 (MM) |

Flute Length L1 (MM) |

Total Length L (MM) |

Shank Dia. D(MM) |

| 1-4*D4-50L | 1-4 | 4 | 50 | 1-4 |

| 4*75L*D4 | 4 | 12 | 75 | 4 |

| 4*20*100L | 4 | 20 | 100 | 4 |

| D6*15*D6*50L | 6 | 15 | 50 | 6 |

| D6*24*D6*75L | 6 | 24 | 75 | 6 |

| D6*30*D6*100L | 6 | 30 | 100 | 6 |

| D8*20*D8*60L | 8 | 20 | 60 | 8 |

| D8*30*D8*75L | 8 | 30 | 75 | 8 |

| D8*35*D8*100L | 8 | 35 | 100 | 8 |

| D10*25*D10*75L | 10 | 25 | 75 | 10 |

| D10*40*D10*100L | 10 | 40 | 100 | 10 |

| D12*30*D12*75L | 12 | 30 | 75 | 12 |

| D12*40*D12*100L | 12 | 40 | 100 | 12 |

| D14*40*D14*100L | 14 | 40 | 100 | 14 |

| D16*40*D16*100L | 16 | 40 | 100 | 16 |

| D18*45*D18*100L | 18 | 45 | 100 | 18 |

| D20*45*D18*100L | 20 | 45 | 100 | 20 |

| D6*45*D6*150L | 6 | 45 | 150 | 6 |

| D8*50*D8*150L | 8 | 50 | 150 | 8 |

| D10*60*D10*150L | 10 | 6 | 150 | 10 |

| D12*60*D12*150L | 12 | 6 | 150 | 12 |

| D14*70*D14*150L | 14 | 70 | 150 | 14 |

| D16*70*D16*150L | 16 | 70 | 150 | 16 |

| D18*70*D18*150L | 18 | 70 | 150 | 18 |

| D20*70*D20*150L | 20 | 70 | 150 | 20 |

Customization Services Are Acceptable

Features

● High-quality tungsten carbide materials

● Sharp edge, durable wear unique down chip removing design.

● High process reliability and higher production efficiency.

● Precision machining &Quality guarantee

● Long service life and fast delivery.

Tungsten Carbide End Mill

01 WIDE APPLICATION

Recommend The Suitable Processing

Applicable Field To Achieve The Maximum Value

02 THE SERVICE LIFE IS LONG

Excellent Toughness &High Wear Resistance

Stable Performance

03 QUALITY ASSURANCE

100% Quality Assurance

For More Than 15 Years Experience

Photos

Carbide Flatten End Mill

Carbide Corner Radius End Mill

Carbide 4 Flutes End Mill With Coating

Carbide Ball Nose End Mill

HRC55 Ball Nose Endmill

Solid Carbide End Mill With Coating

Advantage

● Fully enables running at rough machining parameters, resulting in finish surface quality.

● Excellent performance in machining titanium, stainless steel and high temperature alloys.

● The coating provides longer tool-life or increased cutting-values.

● Suitable for all types of steel or metal.

Application

Carbide end mill using for cutting Copper, Cast Iron, Carbon steel,Tool steel,Mould steel,Die steel, Stainless steel,Plastic, Arcylic etc. And widely used in aerospace,transportation, Medical equipment,Military manufacturing,Mould development,Apparatus and Instrument etc.

OUR QUALITY CONTROL

Quality Policy

Quality is the soul of products.

Strictly process control.

Zero tolerate of defects!

Passed ISO9001-2015 Certification

Production Equipment

Wet Grinding

Spray Drying

Press

TPA Press

Semi-Press

HIP Sintering

Processing Equipment

Drilling

Wire Cutting

Vertical Grinding

Universal Grinding

Plane Grinding

CNC Milling Machine

Inspection Instrument

Hardness Meter

Planimeter

Quadratic Element Measurement

Cobalt Magnetic Instrument

Metallographic Microscope