MWD & LWD Parts Tungsten Carbide Poppet End And Orifice For Drilling Tools

Description

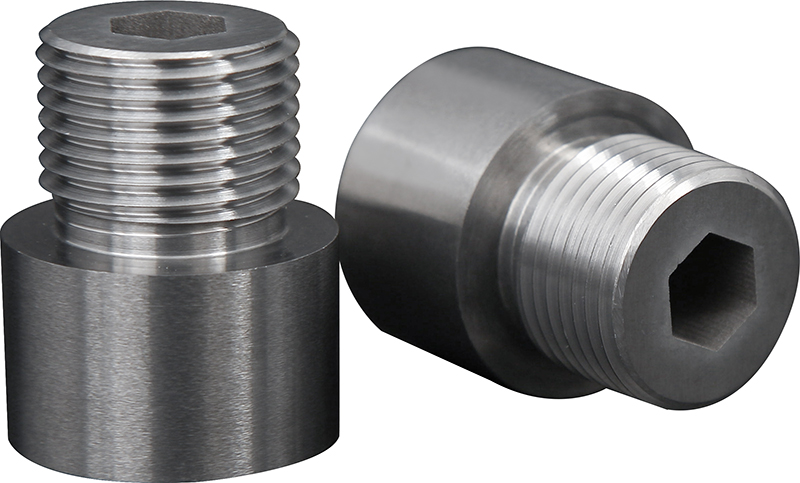

The tungsten carbide poppet end for MWD and LWD are mainly used for the function of flushing, slurry sealing, flow diversion, and sending slurry pressure and other information back with pulse signal. The tungsten carbide main valve core is one of them used in MWD and LWD. Different specifications of the main valve core in use can produce different pressure signals, easy to adjust the pressure signal strength according to well conditions, well depth and other factors.

Our factory using high-quality Chinese brand raw materials to produce the poppet tip ensure wear resistance.The carbide poppet end adopts HIP sintering technology to ensure density more uniform.And it can effectively reduce or eliminate residual pores in hard alloys. Improve the bending strength and fatigue life of carbide.

Our advanced CNC semi-finishing process ensures that every Poppet End is manufactured with utmost precision. This computer-controlled machining technique guarantees consistent dimensions, smooth finishes, and tight tolerances, resulting in a product that perfectly adheres to customer require.

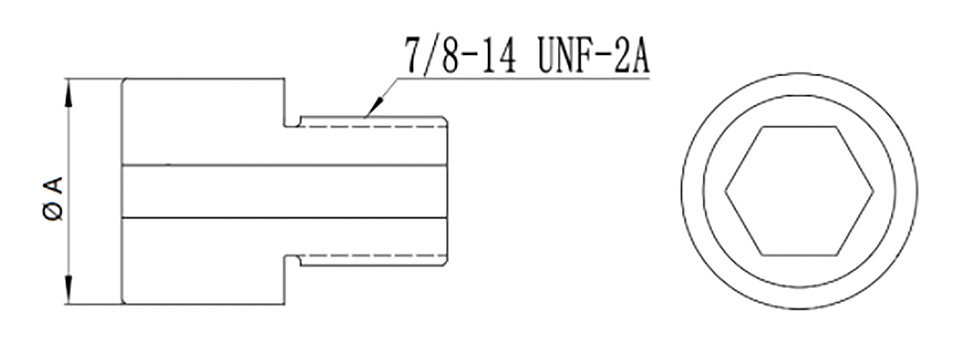

Parameter

Poppet End is made of tungsten carbide material.The 7/8-14 UNF-2A threaded portion of the poppet is precision ground using precision CNC machines. This meticulous manufacturing process ensures the highest accuracy and consistency in threading. With this level of accuracy, you can trust that each poppet tip will fit seamlessly into your drilling equipment.Our experienced team can machine difficult internal threads to your specific drawing requirements, ensuring the poppet is a perfect fit for your tools.

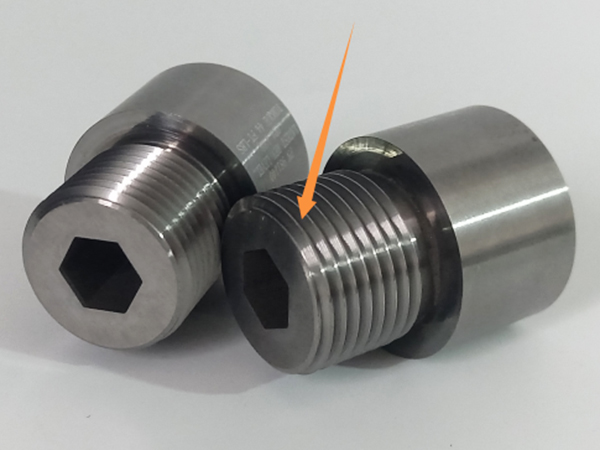

Laser marking for quick size verification and traceability.

Specifications

Carbide Poppet End

| Item | OD size | Thread |

| 981213 | Ø1.086’’ | 7/8-14 UNF-2A |

| 981214 | Ø1.040’’ | 7/8-14 UNF-2A |

| 981140 | Ø1.122’’ | 7/8-14 UNF-2A |

With various size options available, ranging from OD1.086’’, 1.040’’, 1.122’’,We can also accepted be customized according to customer’s requirements. And more, you can find the perfect fit for your drilling tool requirements.

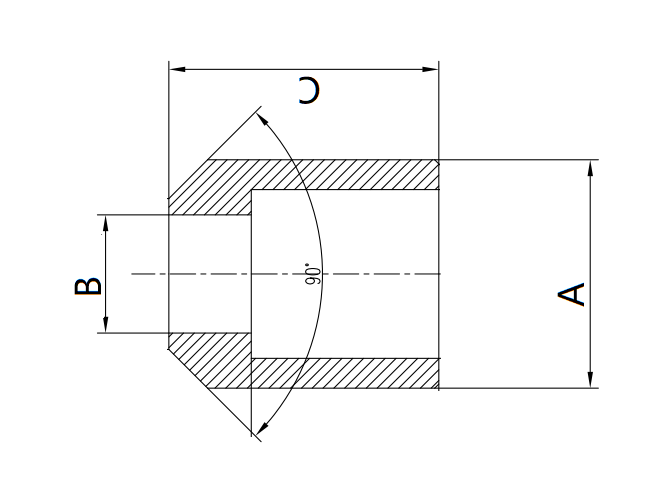

Carbide poppet Tips P360

| ØA | ØB | ØC |

| 1.04'' | 0.57'' | 1.30'' |

| 1.086'' | 0.57'' | 1.30'' |

| 1.125'' | 0.57'' | 1.30'' |

| 1.16'' | 0.57'' | 1.30'' |

Carbide poppet some grades as follows:

| Grades | Physical Properties | Major Application And Characteristics | ||

| Hardness | Density | TRS | ||

| HRA | g/cm3 | N/mm2 | ||

| CR35 | 88.5-89.5 | 14.30-14.50 | ≥2800 | It is suitable to produce sleeves bushings and nozzles due to high hardness and good wear-resistance, |

| CR06N | 90.2-91.2 | 14.80-15.00 | ≥2560 | It is suitable to produce sleeves and bushings used in oil & gas industry due to excellent corrosion & erosion resistance, |

Our Advantages

● Short and on time delivery

● High precision size controlled

● Good wear resistance

Our Services

● Grade certificate

● Dimension and material testing and approval

● Samples analysis is available

You may also like

Poppet Tip

Booster Ring

Servo Orifice Pulser

Regular 350/650 Pulser Orifice

Production Equipment

Wet Grinding

Spray Drying

Press

TPA Press

Semi-Press

HIP Sintering

Processing Equipment

Drilling

Wire Cutting

Vertical Grinding

Universal Grinding

Plane Grinding

CNC Milling Machine

Inspection Instrument

Hardness Meter

Planimeter

Quadratic Element Measurement

Cobalt Magnetic Instrument

Metallographic Microscope