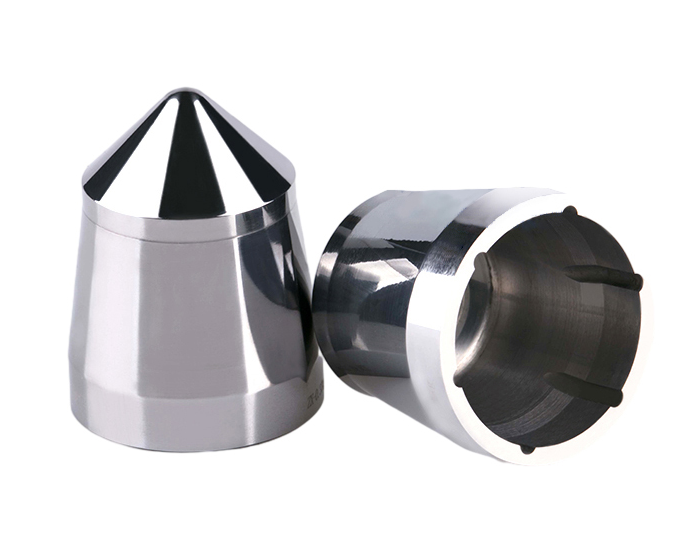

Cemented Carbide Nose Cap 650/1200 For MWD & LWD

Description

The tungsten carbide lift valve is one of used parts in MWD and LWD to help sending slurry pressure and other information back with pulse signal. The tungsten carbide lift valve stretch out and draw back to change the pressure of the mud column and transmits wireless signals.

Tungsten carbide material LWD and MWD precision parts consist many product series:upper pan calve complete,lower pan valve,piston,bushing,nozzle of the liquid flow control and automatic push device of vertical drilling tools,flow deflector,vane wheel,vane wheel axle,vane wheel box,nozzle of the self-activated oscillating-rotating impact drilling tools,lift valve core,flow limitation ring,flow limitation chamfer,nose cap,flow divider,flow,spacer sleeve,pulse hole valve,oscillator of self-activated,upper and lower bearing sleeve and wear sleeve of the pulse generator of MWD and LWD,and nozzle,TC bearing and sleeve of the under well well tools.

Cemented carbide wear parts are mainly used to the vertical well drilling tools,self-activated oscillating-rotating impact drilling tools and MWD and LWD with the functions of flow diversion,flush and seal of slurry and feed back of the slurry pressure and pulse signal in the adverse working conditions of high pressure,high speed flushing of sand and slurry,high temperature,fatigue wear,gas and liquid corrosion in oil and natural gas prospecting.

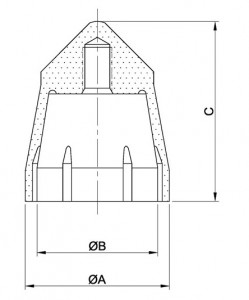

Parameter

| Item | OD size | Thread |

| 981214 | Ø1.040’’ | 7/8-14 UNF-2A |

| 981140 | Ø1.122’’ | 7/8-14 UNF-2A |

Some grades of tungsten carbide lift valve for MWD and LWD are as follows:

| Grades | Physical Properties | Major Application And Characteristics | ||

| Hardness | Density | TRS | ||

| HRA | G/cm3 | N/mm2 | ||

| CR40A | 90.5-91.5 | 14.50-14.70 | ≥2800 | It is suitable to produce sleeves and nozzles used in oil & gas industry due to high hardness and good wear-resistance, |

| CR06N | 90.2-91.2 | 14.80-15.00 | ≥1760 | It is suitable to produce sleeves and bushings used in oil & gas industry due to excellent corrosion & erosion resistance, |

Quality Control:

● All raw materials are tested in terms of density, hardness and TRS before use

● Every piece of product goes through in-process and final inspection

● Every batch of product can be traced

● Advanced technology , automatic pressing,HIP sintering and precision grinding

● All abrasion resistance carbide wear parts are made by WC and Cobalt or Nickel , which is excellent in wear resistance

● Certificates & Quality Control

● Advanced production equipment and testing equipment

Production Equipment

Wet Grinding

Spray Drying

Press

TPA Press

Semi-Press

HIP Sintering

Processing Equipment

Drilling

Wire Cutting

Vertical Grinding

Universal Grinding

Plane Grinding

CNC Milling Machine

Inspection Instrument

Hardness Meter

Planimeter

Quadratic Element Measurement

Cobalt Magnetic Instrument

Metallographic Microscope