Custom Tungsten Carbide Plungers Used In High Pressure Pump

Description

Tungsten Carbide Plunger is used for high-pressure pumps because tungsten carbide materials provide the best wear-resistant ability.Carbide plungers can be used in high-temperature applications, up to 500°F and up to 10,0000psi.

The main features of Zhuzhou Chuangrui tungsten carbide plunger are stable mechanical properties, high wear resistance and high impact resistance.

Zhuzhou Chuangrui factory offers different sizes of tungsten carbide plungers by inches.

Photos

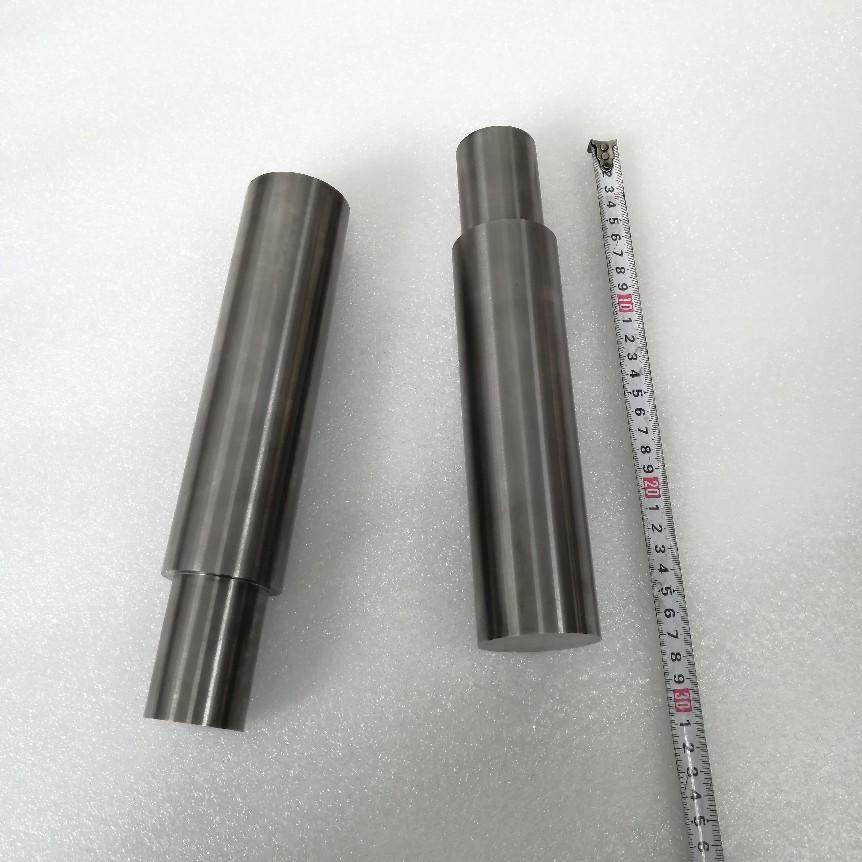

Tungsten carbide Plungers

Large size carbide plunger rod

Carbide plungers

Solid tungsten carbide plungers

No-magnet tungsten carbide plunger

carbide pistons

Tolerance of carbide high-pressure pump plungers:

The tolerance of carbide plungers is an important factor to consider in their design and manufacturing process. In high-pressure pump applications, the tolerance of the plungers is typically very tight, with allowable deviations often measured in microns.

The manufacturing process for carbide plungers involves precision machining to achieve the required tolerances. CNC machines and other advanced manufacturing technologies are often used to produce carbide plungers with the required precision and accuracy.

The tolerance required depends on the specific application and the level of precision needed for the plungers to function correctly within the pump. The manufacturing process typically involves precision machining, and factors such as temperature, pressure, and vibration must be considered when selecting carbide plungers for a particular application.

The tungsten carbide grade of the tungsten carbide plunger:

Most tungsten carbide plungers are needs very good at wear resistance when the plungers work on the pump. Our technology suggesting to used tungsten carbide CR8X which 8% of cobalt as a binder and 92% of tungsten will normally suit the application, 5000 psi to 40000psi. another CR15X of tungsten carbide grade is for higher pressure up to 100000. Map.CRN grade is for special applications when no magnet is requested. all CRN tungsten carbides are no-magnet. this grade is perfect for a no-magnet tungsten carbide plunger.

Production Equipment

Wet Grinding

Spray Drying

Press

TPA Press

Semi-Press

HIP Sintering

Processing Equipment

Drilling

Wire Cutting

Vertical Grinding

Universal Grinding

Plane Grinding

CNC Milling Machine

Inspection Instrument

Hardness Meter

Planimeter

Quadratic Element Measurement

Cobalt Magnetic Instrument

Metallographic Microscope