In key fields such as aerospace and energy, high-temperature carbide have become indispensable materials due to their excellent high-temperature performance. However, high-temperature carbide face many challenges in the machining process - high material strength, high viscosity, significant work hardening tendency, and poor thermal conductivity at high temperatures, which make machining extremely difficult and require higher material requirements for blades. To assist customers in improving processing efficiency and quality, our company has launched a new high-temperature carbide material processing grade CR20X with deep technical accumulation and continuous innovative research and development.

In key fields such as aerospace and energy, high-temperature carbide have become indispensable materials due to their excellent high-temperature performance. However, high-temperature carbide face many challenges in the machining process - high material strength, high viscosity, significant work hardening tendency, and poor thermal conductivity at high temperatures, which make machining extremely difficult and require higher material requirements for blades. To assist customers in improving processing efficiency and quality, our company has launched a new high-temperature carbide material processing grade CR20X with deep technical accumulation and continuous innovative research and development.

Core technological advantages

Optimize ingredients and processes to create excellent high-temperature strength

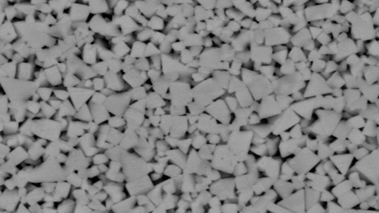

The CR20X brand has successfully constructed a more reasonable distribution of the third phase microstructure through dual optimization of composition and process. This carefully designed microstructure can effectively alleviate material softening and structural failure caused by high temperatures, providing a solid guarantee for the stability of cutting tools under harsh processing conditions.

The CR20X brand has successfully constructed a more reasonable distribution of the third phase microstructure through dual optimization of composition and process. This carefully designed microstructure can effectively alleviate material softening and structural failure caused by high temperatures, providing a solid guarantee for the stability of cutting tools under harsh processing conditions.

Dual resistance capability, improving processing efficiency and lifespan

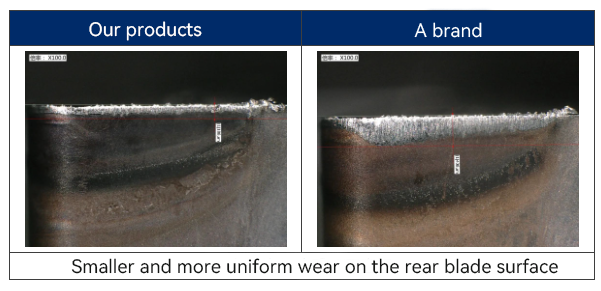

The CR20X brand has excellent resistance to high temperature plastic deformation and anti chipping ability. Plastic deformation of materials at high temperatures can cause changes in the tool groove structure, affecting machining accuracy and efficiency. And CR20X, with its unique material properties, can effectively resist this deformation, ensuring that the tool maintains precise geometric shape during long-term machining. Reduced the risk of blade breakage and significantly extended the service life of the cutting tool.

High temperature tough substrate

Reasonable particle size distribution

Create value for customers

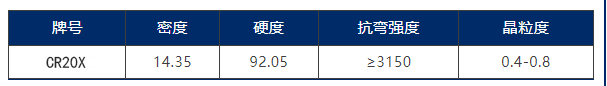

Materialperformance

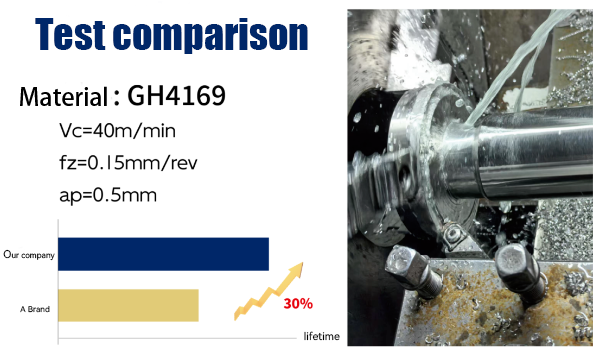

Application Cases

Under the same operating conditions, using CR20X grade blades significantly improves processing efficiency, effectively shortens production cycles, and helps customers reduce time costs. Meanwhile, the longer processing life reduces the frequency of tool replacement, lowers the cost of tool consumption, and further enhances the economic benefits for customers. In addition, stable machining performance also helps to improve the surface quality of machining and meet high-precision machining requirements.

Under the same operating conditions, using CR20X grade blades significantly improves processing efficiency, effectively shortens production cycles, and helps customers reduce time costs. Meanwhile, the longer processing life reduces the frequency of tool replacement, lowers the cost of tool consumption, and further enhances the economic benefits for customers. In addition, stable machining performance also helps to improve the surface quality of machining and meet high-precision machining requirements.

Our company is always customer-oriented and committed to providing higher quality and more efficient solutions for the field of high-temperature alloy processing. The launch of the new CR20X brand is another technological breakthrough for us in this field. We look forward to working together with our customers to tackle the challenges of high-temperature carbide processing and create a new realm of processing.

Post time: Apr-18-2025